What Applications Can You Use the Emaxx Continuous Flow Water Heater for

In the 35 years since direct hot water systems entered the UK commercial market, applications have encompassed ever more energy efficient solutions, including condensing technology and, increasingly, fast response 'instant', or continuous flow water heating. This CPD will consider the reasons that, properly applied, such systems can provide reduced energy consumption compared to traditional systems, so reducing the potential lifetime carbon impact and making a positive contribution to meet regulatory requirements such as the UK Building Regulations.

Instantaneous water heaters are well established and popular in many parts of the world (typically as 'point of use' or 'multipoint' heaters). Due to advances in materials, manufacturing methods and control techniques, in recent years instantaneous heaters have also evolved into 'continuous flow' water heaters. The principal factors that differentiate continuous flow water heaters from the former instantaneous water heaters are the close control systems that are used to maintain accurate control of the hot water temperature at high efficiencies, during both continuous and intermittent operation. This is achieved through application of microprocessor controllers together with fast response sensors, combined with fully modulating control of the combustion process.

When combustion takes place in a gas-fired water heater, it produces heat in the form of: radiation from the flame and the gas jet/burner assembly; convection due to the increased temperature of the gases post combustion; and latent heat in water vapour produced in the chemical process (that will not be available as useful heat until the water vapour condenses).

Methane is the principal constituent of natural gas (about 95%). A simplified combustion equation for the most effective combustion of methane (given in moles) is:

However, typically in a gas boiler, 20% excess air (that is, a lambda of 1.2) will be used to ensure full combustion of the methane giving:

where the excess air would be evidenced by oxygen being present in the discharged flue gases. The excess air will also reduce the temperature of the gases leaving the combustion process, and reduce the transfer of heat to the water passing through the heat exchanger. The operating effectiveness of the water heater will improve with closer control of lambda to ensure that just enough excess air is supplied. Approximately every 1% extra oxygen supplied in the excess air results in 0.5% efficiency loss.1 (For an explanation of stoichiometric ratios and lambda, see the August 2012 CIBSE Journal CPD.)

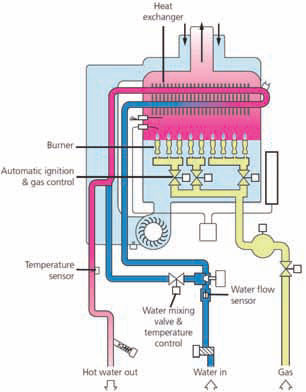

Figure 1: A continuous flow condensing hot water heater

In a modern continuous flow water heater, such as that shown in Figure 1, the controller alters the combustion air and gas rates to ensure a near stoichiometric air to gas volume ratio, to maintain the most effective combustion at all points of operation. Water is heated only while it is flowing – a water flow sensor measures the water flow and sends a signal to the controller. The controller monitors the temperature of the water passing through the system and calculates how much combustion air and gas is required to achieve the required increase in water temperature. Typically, an outlet water low thermal inertia thermistor (that is, one with a fast response time) measures the temperature of the water being produced and maintains the desired water outlet temperature.

Should the water flow rate exceed the capacity of the water heater, a water flow control valve will reduce the flow of water to maintain the set temperature. A variable speed fan, complete with a fan rotation sensor, is used in conjunction with the modulating gas valve to supply the correct amount of gas. Feedback information provides virtually instant error signals to the gas and water controller so that it is able to provide rapid responses to a change in demand for hot water or a change in temperature requirements. The system maximises system efficiency and, by tightly controlling the combustion process, also minimises the emissions of NOx that will increase as excess oxygen rises and reacts with N2 in the high temperature area of the flame.

Safety is assured by the controller continuously monitoring the system components, including both a flame sensor checking for correct ignition and exhaust flow sensing.

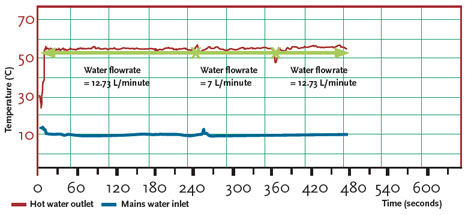

Figure 2: Hot water temperatures at varying flowrates, from an example condensing continuous fl ow water heater with a design maximum load of 54kW

The output from such a heater can be very stable – an example heater (tested as per EN132032) provides the outlet hot water temperatures shown in Figure 2, where the hot water draw-off rate starts at 12.73 L/minute, then instantaneously reduces to 7 L/minute and then reverts to 12.73 L/minute. The temperature of the hot water remains stable within a few degrees of a set point (in this case, 55°C).

Water heater operating efficiencies

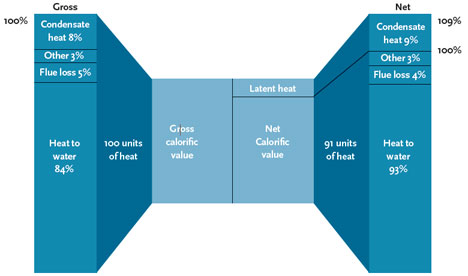

Efficiencies are variously quoted both in terms of 'net' and 'gross' efficiency. Gross efficiency calculations will include all the energy available from the fuel, including the energy due to the latent heat (water vapour) in the flue gas (an additional potential heat source of 3.6 MJ per m3 refined natural gas out of the available total of 38 MJ/m3).3 Hence, net efficiencies are higher than gross, as illustrated in the comparison in Figure 3. In theory, the latent heat can be fully recovered if, somewhere in the water heater, before the flue gases are expelled they are cooled to less than 20°C. Condensation will start at 57°C, and at a gas temperature of 30°C, approximately 70-80% of latent heat will be recovered.1 Historically, the UK has used gross calorific values, but since EU standards apply net values, this has now become the more frequently applied standard.4

Figure 3: Gross and net calorific values for natural gas

The true 'thermal efficiency' of a domestic water hot water system is the useful energy delivered (through hot water at the point of use) divided by the energy consumed (for example, in the form of gas, oil and electricity). However, to calculate this in practice will be diffi cult, since it is dependent on the incoming mains water temperatures and the pa ttern of usage (and associated distribution losses).

Direct and indirect water heating are not easy to compare, but at full load well installed systems are unlikely to show great differences in primary energy conversion (for example, burning of gas). However, it is the transfer of the heat to the water, both at full load and part load, where a direct-fi red water system is likely to benefit.

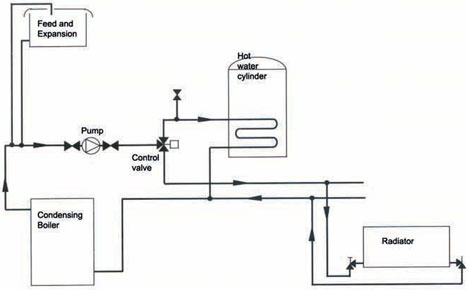

The overall efficiency of a conventional condensing boiler linked in with a secondary hot water storage vessel (as shown in Figure 4) will be limited, due to the losses in the primary heating circuit and hot water cylinder but, more importantly, due to the lack of potential for condensing operation during times of low domestic hot water consumption.

Figure 4: Example heating and domestic hot water schematic

Stored hot water needs to be maintained at 60°C (to prevent problems of Legionella as required by HSE L85) for at least one hour per day. The store will lose heat to the surrounding environment – for example, the Non-Domestic Heating, Cooling and Ventilation Compliance Guide6 (the supporting document to the UK Building Regulations) indicates a (recommended maximum) heat loss of 4.7 kWh per day for a 1,000 litre domestic hot water cylinder. The same loss will be evident with any storage water condensing heating system, including direct-fi red systems.

During periods when there is little or no hot water draw-off, if the stored water is to be maintained at 60°C, the primary top up heating feed in the storage vessel will have water returning to the boiler at a temperature greater than 60°C. Since condensing boilers require return water temperatures of below 57°C to operate in condensing mode, it can be challenging at times of low hot water load to operate at its expected condensing efficiency. It should, however, be noted that with careful design the cold water feed into the cylinder can be arranged to maximise the opportunity of keeping the primary return at a lowest possible temperature when used in association with indirect condensing boilers.

A condensing continuous flow water heater system (as shown in Figure 1) is constantly fed with water from the mains supply (at approximately 10°C), and this provides the opportunity for it to operate in fully condensing mode at all times.

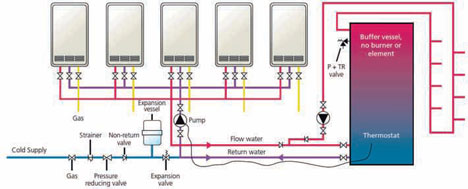

The range of commercially available continuous hot water heaters can supply from around 100 L/hour to more than 1,000 L/hour. However, where there is a requirement for storage – for instance, if there are huge spikes in demand – they can be used as single or multiple units to serve a storage vessel, as in Figure 5. This will allow a turndown to just a few percent of peak while maintaining high combustion efficiencies. Similar arrangements, but using a common thermal store, allow instantaneous hot water heaters to work in conjunction with LZC sources – such as air and ground source heat pumps – to efficiently lift the temperature of the pre-heated water. For direct gas-fired water heaters to condense will depend on the storage tank design and how the feed water is introduced.

Figure 5: Multiple condensing continuous flow water heaters linked to provide high volume domestic hot water store

Meeting the thermal regs

The Building Regulations Part L2 and, more particularly, the Non-Domestic Heating, Cooling and Ventilation Compliance Guide, explicitly recognise that the gross efficiency of the primary heater in a direct-fired water heater is allowed to be lower than that of a boiler used by an indirect hot water heating system. The Compliance Guide requires a minimum gross efficiency for direct natural gas-fired water heaters of 73%, compared to the minimum (seasonal) efficiency of a boiler being used to indirectly generate hot water of 80%. The indirect boiler requirement is quoted as 'seasonal' to take account of the variability in performance, as primary return temperatures, and boiler losses, vary in use. In a direct-fired water heater system, there will be fewer opportunities for energy loss (no primary pipework, and the fuel consumed will be directly linked to the water heated) so although the required efficiency of the heat source is lower, it is likely that the overall installed 'true' efficiency will be higher. When comparing solutions for the combined provision of space heating and hot water with that of a direct water heating system, it is important to consider the 'whole season efficiency' rather than only peak loads. (Detailed guidance is available in BS EN 15316-3-3:2007 Heating systems in buildings. Method for calculation of system energy requirements and system efficiencies. Domestic hot water systems, generation.)

The National Calculation Method (NCM), often using the Simplified Building Energy Model (SBEM) is used to assess compliance with the 2010 Building Regulations. This procedure, used for buildings other than dwellings, compares the proposed design with the benchmark energy use of a comparable 'notional' building. The Compliance Guide and the Building Regulations recognise that the appropriate control mechanism is so important that extra 'heating efficiency credits' of 1.5% (in the comparison of the actual installed system with the notional system) is given for fully automated ignition and integrated combustion controls. As with all water heating systems, the importance of proper selection and design procedures is recognised by an allowance of an extra 2% being added to the calculated installed efficiency for the purposes of the NCM.

Despite the UK market offering high efficiency hot water heaters for more than a third of a century, with condensing and continuous flow providing proven solutions, only something less than 2%1 of UK installations use the technology. Where there is an appropriate hot water load to afford the installation of a split space and hot water heating, continuous flow hot water heaters can provide a flexible and efficient option.

© Tim Dwyer 2013

References:

- Kemna, R. et al, Preparatory Study on Eco-design of Water Heaters, Task 4 Report, VHK/EU Commission, 2007.

- BS EN 13203-2:2006 Gas-fired domestic appliances producing hot water. Appliances not exceeding 70 kW heat input and 300 l water storage capacity. Assessment of energy consumption.

- http://chp.decc.gov.uk/cms/calorific-values/ accessed 4 February 2013.

- CIBSE Knowledge Series: KS14, Energy efficient heating: an overview, CIBSE, 2009.

- Legionnaires' Disease. The control of legionella bacteria in water systems. Approved Code of Practice and Guidance L8, HSE, 2000.

- Non-Domestic Heating, Cooling and Ventilation Compliance Guide, DCLG, 2010.

Complete the questionnaire

stuartuposecushers.blogspot.com

Source: https://www.cibsejournal.com/cpd/modules/2013-03/